Center for Advanced Polymer and Composite Engineering (CAPCE)

The Ohio State University (lead institution)

A National Science Foundation Industry/University Cooperative Research Center since 1997

Partner Institutions:

- Florida State University

- University of Wisconsin at Madison

Fundamental advances and technology development benefit the polymer and composite processing industry

|

Center Mission and Rationale

The dynamic and expanding polymer industry is one of the few industries in which the United States maintains strong leadership in an extremely competitive global market. CAPCE fosters increased collaboration among applications researchers in industry and fundamental researchers in universities, to enable more rapid modernization and commercialization of new ideas. The Center addresses the need for industry-university collaboration by building a base of research, engineering education, and technology transfer, resulting in improved industrial practice and productivity.

Research Program

CAPCE's interdisciplinary research is supported by industry (over 20 companies are active members), the National Science Foundation, the State of Ohio's Thomas Edison Program, and The Ohio State University. The research concentrates on manufacturing polymeric materials via melt, powder, and reactive liquids, and forming from sheet and bulk materials. Interactions among materials, part design, processing conditions, and product properties are key concerns. The program is structured according to the four areas of emphasis described below.

The Thermoplastic Processing thrust area focuses on polymer rheology and advanced processing techniques such as injection molding (IM), gas-assist and thin-wall IM, and extrusion technology. Both this and the following area of emphasis address demands for reduced part weight and faster cycle times while maintaining part strength and appearance.

|

The Thermoset Polymers and Composite Manufacturing thrust area studies resins, fibers, composites, and nanocomposites. Some of the current projects include material characterization, process analysis and modeling of liquid molding processes (RTM, SCRIMP and injection-pultrusion), development and characterization of low pressure SMC and BMC, application of low-profile additives to composite processing, in-situ permeability measurement, and carbon nanotube reinforced composites.

The Integral Attachment (Snap-Fit) Design thrust area is advancing snap-fit design from an art to an engineering science. The goal is to develop snap-fits with at least an order of magnitude increase in performance as compared to conventional designs. This will allow the use of snap-fits in applications for which they are currently not suited.

The Integrated Development of Composite Products and Processes thrust area studies the various life cycle issues regarding affordable composite materials using an integrated product and process development approach. The goal is to make advanced composite materials affordable through the development and deployment of process modeling, design optimization, lifecycle cost estimation, and statistical process control.

Technology Deployment

Examples of CAPCE's research advances that are improving industrial practice include:

-

A comprehensive analytical tool for characterizing and simulating the liquid composite molding (LCM) process was developed and successfully applied to industrial applications at Dow Chemical, GenCorp, and General Motors. Some of the code was adapted to a commercial software package, C-SET, for wider usage.

- Effects of macro- and micro-voids on mechanical properties in liquid composite molding were investigated and a model developed. A patent was shared with industry for "A Computer Code Capable of Simulating Dry Spot Formation and Changes in Liquid Composite Molding."

- The Geon Company is using CAPCE computational tools to aid in optimizing PVC compound processing. A computational flow simulation predicts the level of PVC degradation throughout a molded part. This simulation is used by part designers and molders to eliminate or reduce degradation of PVC compounds.

- U.S. Precision Lens obtained stiffness data from the Integral Attachment facility. Lens housings were tested and the data combined with CAPCE-developed models to develop a new generation of lens housings, yielding increased production, higher strength, and overall cost savings.

- More than 20 new technical reports are released each year to industry members. In addition, scores of visits and demonstrations transfer new CAPCE innovations in polymer and composite engineering to industry.

- Regional workshops introduced the latest snap-fit technologies and modeling approaches to 500 industry participants.

- A comprehensive, integrated manufacturing and quality control tool was developed and validated against Lockheed Martin Missiles and Fire Control-Orlando's composite structures and production data.

Facilities

Over $4 million in modern equipment is housed in the laboratories below.

- Investigators at the injection molding facility evaluate injection molding processes in conventional, gas-assisted, and thin-wall applications.

- Research at the extrusion facility investigates supercritical

fluids-enhanced polymer/composite blending and microcellular foaming.

- The rheologic measurement facility helps researchers characterize the behavior of materials by measuring the viscous and viscoelastic properties of polymers.

- Work at the composite manufacturing facility emphasizes reactive liquid molding, injection pultrusion, in-mold coatings, electronic pre-pregs, sheet molding compound manufacturing, compression molding, and accelerated aging.

- The mechanical testing facility evaluates the mechanical performance of plastic part assemblies by testing existing and proposed snap-fit designs.

- Research at the analytical facility characterizes the behavior of polymers by measurement and analysis, reaction kinetics, strength and surface quality, and permeability and shrinkage.

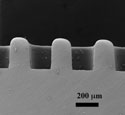

- A microfabrication facility develops polymer-based microfabrication technology in precision injection molding, embossing, and reactive molding for new applications in bio- and chemical-MEMS and other industries.

Center Headquarters

Center for Advanced Polymer and Composite Engineering

The Ohio State University

437 Koffolt Labs

140 W. 19th Avenue

Columbus, OH 43210-1180

Tel and Fax (614) 292-9271

Homepage: www.capce.ohio-state.edu

Center Director: Dr. L. James Lee

(614) 292-2408 * lee.31@osu.edu

Research Site at Florida State University

Florida Advanced Center for Composites Technologies

Site Director: Dr. Ben Wang

Tel (850) 410-6339 * Fax (850)410-6377

indwang1@eng.fsu.edu

Research Site at University of Wisconsin-Madison

Engineering Polymer Industrial Consortium (EPIC)

of the Polymer Engineering Center (PEC)

Site Director: Dr. Tim A. Osswald

Tel (608) 263-9538 * Fax (608) 265-2316

tim@danu.me.wisc.edu

Center Evaluator: Scott Morris

(217) 351-0910 * smorris@xindium.com

NSF 01-168k