Center for Advanced Engineering Fibers and Films (CAEFF)

Clemson University and Massachusetts Institute of Technology

![]()

Creating a new paradigm for fiber and film development

| A National Science Foundation Engineering Research Center since 1998 |

The Center for Advanced Engineering Fibers and Films (CAEFF) provides an integrated research and education environment for the systems-oriented study of fibers and films. To control structure in polymeric fibers and films, industries need a complete science base, computational models that integrate molecular information with continuum or microscopic-level models, and advanced visualization tools as well as a new generation of engineers and scientists with experimental, modeling, and visualization expertise. CAEFF will promote the transformation from trial-and-error development to computer-based design of fibers and films.

Research

|

| Center research teams simulate the molecular structure of fibers and films in a virtual environment with the Concurrent Technologies Virtual Workbench. Contact gloves, joysticks, and electromagnetic tracking devices are used to navigate through the three-dimensional scene. |

Complementary modeling/visualization and experimentation tasks are organized into three research thrusts: (1) Computer-based Product/Process Development, (2) New Fiber and Film Precursors, and (3) Advanced Fiber and Film Processes. Each thrust is creating integrated models that will identify potential precursors for given fiber and film applications, simulate their response to processing and in-service environments, predict process conditions that might yield optimal product performance, and guide future process and product development. To facilitate understanding of these complex systems, computational models will be linked to visualization at all levels, from the atomistic through process simulation. Student research projects will be used to test models for individual process steps as well as the complete simulation package at CAEFF partner companies. Integrative testbeds couple research efforts and education innovations. The research program will deliver a comprehensive science base, complete simulation packages (computational models utilizing advanced visualization techniques), and new/improved products and processes.

Education

Aligned with the research program is the Center's education program, which seeks to provide its students with an integrative, systems-oriented background in fibers and films. The goals for the education program include:

- bringing change in the culture of engineering education

- infusing CAEFF's next-generation engineered systems research into the Clemson/MIT curricula

- developing a generation of future industrial leaders who are more effective in a global economy

- increasing the diversity of the engineering workforce

- attracting young students to engineering and science, with a focus on the fiber and film industries

- advancing the skills of the technical workforce.

|

| In the Center's integrative fiber/film formation laboratory, Killian extruders spin bi-component polymer filaments designed using computer models. Researchers can study the polymeric structure both by observing the fibers as they form and by visualizing the fibers in the virtual domain. |

CAEFF's education program has four components: undergraduate, graduate, pre-college, and post-college. All emphasize a systems approach to formulating and solving problems, integration of multiple perspectives, hands-on research experiences, and communication skills. CAEFF encourages cross-cultural, collaborative learning; research projects are tackled by teams of undergraduates, graduate students, university faculty members, and industry personnel. The Master of Science Industrial Residency Program, in which graduate students conduct industry-defined research on site, typifies the Center's emphasis on an industry perspective. Several new courses have been developed to serve the research/education mission of the Center.

CAEFF has particularly active K-12 outreach programs. The Research Experiences for Undergraduates (REU) program provides undergraduates with an opportunity to join interdisciplinary teams solving industrially relevant problems. High school students from the South Carolina Governor's School for Science and Mathematics also participate on these REU teams. A partnership with the NSF-funded Anderson-Oconee-Pickens Hub places graduate students and industry personnel in the public schools as scientists-in-residence to support use of Center-developed engineering kits.

Industrial Collaboration/Technology Transfer

CAEFF's industrial collaboration program is designed to create a trusted partnership between industry and academe. To establish mutually beneficial relationships with fiber and film companies, we have identified several goals: partnering with a range of companies from representative industry sectors; involving industry in planning, research, and education; identifying mechanisms by which industry can provide financial and other support; and establishing a multifaceted technology transfer program.

|

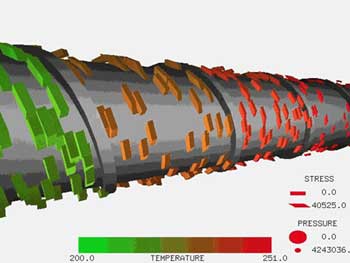

| Visualization of polymer deformation during flow through a spinnerette. |

CAEFF has commitments for both financial support and active participation by major fiber and film manufacturers. Industry segments targeted for CAEFF membership include producers of polymers and chemical additives, textile companies, suppliers, customers of the fiber and film industries, equipment manufacturers, and software/hardware developers.

To provide avenues for significant interaction between industry and other Center participants, we have set up three membership options for companies: Full Partner ($100,000 or more), Sponsoring Partner ($50,000 to $99,000), and Limited Partner ($5,000 to $49,000). Companies have several options for participation, including the Industrial Residency Program, unrestricted support of programs and activities, sabbatical interchanges, co-advising, testbed development, and direct support of specific research projects in Center laboratories.

CAEFF technology transfer mechanisms include computer software containing center-generated process models, short courses, and sponsorship of workshops and conferences such as the annual Fiber and Film Producer Exposition and concurrent Fiber and Film Producer Technical Conference at the Palmetto Exposition Center in Greenville, SC. The exposition draws over 2,000 attendees and has become the major technical forum for the fibers and films segments of the materials industry.

|

| Visual model of flow through the barrel of a polymer extruder. |

Facilities

Administrative offices, videoconference and meeting rooms, integrative testbeds, the molecular modeling and virtual reality laboratories, and student study and meeting space are all located in Rhodes Engineering Research Center.

Systems-Level Testbeds

In CAEFF's integrative testbeds, pilot-scale fiber and film processes are directly linked to the Center's computer-based simulation/visualization system. These testbeds allow Center researchers to test and/or demonstrate new visual simulation packages and confirm predictions on-line. For instance, the researcher can change the extrusion temperature and view the predicted response (thermal, stress, structure and properties) in the visual domain, while observing the actual response of the pilot-scale fiber or film process. These testbeds are powerful tools for both research and teaching. A fiber and film characterization testbed contains instrumentation that provides physical, chemical, structural and rheological measurements necessary to meet Center research goals. During the first five years, other testbeds will be established at Clemson University in fiber and film formation; modeling, simulation, and visualization; and process development. In later years customer-oriented testbeds for fiber and film performance in end-use applications and software usability will be phased in.

Center Configuration, Leadership, Team Structure

|

| Undergraduates and high school students participate in research teams in CAEFF's summer REU program. |

To implement its research/education programs, the Center comprises a partnership between Clemson University and the Massachusetts Institute of Technology (MIT) that fuses Clemson's experimental and visualization expertise with MIT's theoretical and modeling expertise. The Center brings together faculty and students from seven disciplines, including materials science and engineering, chemical engineering, chemistry, computer science, mathematical science, mechanical engineering, and textiles, fiber, and polymer science. To address the fiber/film systems issues targeted by the Center's strategic plan, CAEFF's interdisciplinary research teams combine expertise in numerical modeling, visualization, analytical characterization, fiber and film formation, polymer processing, visualization, software development, and usability testing.

![]()

Center Headquarters

Center for Advanced Engineering Fibers and Films

301 Rhodes Engineering Research Center

Clemson University

Clemson, South Carolina 29634-0910

Tel (864) 656-1182 · Fax (864) 656-4557

E-mail: caeff@ces.clemson.edu

Homepage: http://www.clemson.edu/caeff

Center Director: Dr. Dan D. Edie

(864) 656-4535 · dan.edie@ces.clemson.edu

Deputy Director: Dr. John Kennedy

(864) 656-5632 · john.kennedy@ces.clemson.edu

Administrative Director: Ms. Jane Jacobi

(864) 656-1050 · jane.jacobi@ces.clemson.edu

Industrial Liaison: Dr. Ed Booker

(864) 656-6301 · bookerb@clemson.edu

NSF 00-137i