News Release 10-130

Decontaminating Dangerous Drywall

Nanomaterial in novel home-air treatment counters hazards from toxic drywall

Artist's interpretation of FAST-ACT absorbing and destroying toxins.

July 29, 2010

View a video about FAST-ACT powders.

This material is available primarily for archival purposes. Telephone numbers or other contact information may be out of date; please see current contact information at media contacts.

A nanomaterial originally developed to fight toxic waste is now helping reduce debilitating fumes in homes with corrosive drywall.

Developed by Kenneth Klabunde of Kansas State University, and improved over three decades with support from the National Science Foundation, the FAST-ACT material has been a tool of first responders since 2003.

Now, NanoScale Corporation of Manhattan, Kansas--the company Klabunde co-founded to market the technology--has incorporated FAST-ACT into a cartridge that breaks down the corrosive drywall chemicals.

Homeowners have reported that the chemicals--particularly sulfur compounds such as hydrogen sulfide and sulfur dioxide--have caused respiratory illnesses, wiring corrosion and pipe damage in thousands of U.S. homes with sulfur-rich, imported drywall.

"It is devastating to see what has happened to so many homeowners because of the corrosive drywall problem, but I am glad the technology is available to help," said Klabunde. "We've now adapted the technology we developed through years of research for FAST-ACT for new uses by homeowners, contractors and remediators."

The new cartridge, called OdorKlenz®, takes the place of the existing air filter in a home. The technology is similar to one that NanoScale adapted in 2008 for use by a major national disaster restoration service company for odors caused by fire and water damage.

In homes with corrosive drywall, the cartridge is used in combination with related FAST-ACT-based, OdorKlenz® surface treatments (and even laundry additives) to remove the sulfur-bearing compounds causing the corrosion issues.

Developers at NanoScale tested their new air cartridge in affected homes that were awaiting drywall removal, and in every case, odor dropped to nearly imperceptible levels within 10 days or less and corrosion was reduced.

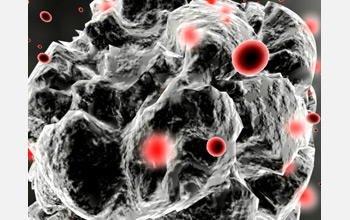

The FAST-ACT material is a non-toxic mineral powder composed of the common elements magnesium, titanium and oxygen. While metal oxides similar to FAST-ACT have an established history tackling dangerous compounds, none have been as effective.

NanoScale's breakthrough was a new method to manufacture the compound as a nanocrystalline powder with extremely high surface area--only a few tablespoons have as much surface area as a football field.

The surface area allows more interactions between the metal oxides and the toxic molecules, enabling the powder to capture and destroy a large quantity of hazardous chemicals ranging from sulfuric acid to VX gas--and their hazardous byproducts--in minutes.

"The concept of nano-sized adsorbents as both a cost-efficient, useful product for first responders and an effective product for in-home use illustrates the wide spectrum of possibilities for this technology," said NSF program director Rosemarie Wesson, who oversaw NanoScale's NSF Small Business Innovation Resarch grants. "It is great to see the original work we supported to help reduce the toxic effects of hazardous spills now expand into other applications."

In coming months, the company is proposing its technology for use in Gulf Coast residences affected by the recent oil spill and other hazardous situations where airborne toxins are causing harm.

In addition to extensive support from NSF, the development of FAST ACT and NanoScale's technology has been supported by grants from the U.S. Army, DTRA, Air Force, DARPA, JPEO, MARCORSYSCOM , the CTTSO, USSOCOM, NIOSH, DOE, NIH and EPA.

-NSF-

-

View Video

This video shows how the FAST-ACT powders work, how they are made and how they are used.

Credit and Larger Version -

These copper coupons show the progressive effects from filtering corrosive gases from the air.

Credit and Larger Version -

Corrosion and damage to copper components is evident on this air-handling system.

Credit and Larger Version

Media Contacts

Joshua A. Chamot, NSF, (703) 292-7730, email: jchamot@nsf.gov

Kyle Knappenberger, NanoScale Corporation, (785) 537-0179, email: KKnappenberger@nanoscalecorporation.com

Principal Investigators

Kenneth Klabunde, Kansas State University, (785) 532-6849, email: kenjk@ksu.edu

The U.S. National Science Foundation propels the nation forward by advancing fundamental research in all fields of science and engineering. NSF supports research and people by providing facilities, instruments and funding to support their ingenuity and sustain the U.S. as a global leader in research and innovation. With a fiscal year 2023 budget of $9.5 billion, NSF funds reach all 50 states through grants to nearly 2,000 colleges, universities and institutions. Each year, NSF receives more than 40,000 competitive proposals and makes about 11,000 new awards. Those awards include support for cooperative research with industry, Arctic and Antarctic research and operations, and U.S. participation in international scientific efforts.

Connect with us online

NSF website: nsf.gov

NSF News: nsf.gov/news

For News Media: nsf.gov/news/newsroom

Statistics: nsf.gov/statistics/

Awards database: nsf.gov/awardsearch/

Follow us on social

Twitter: twitter.com/NSF

Facebook: facebook.com/US.NSF

Instagram: instagram.com/nsfgov